Our development process

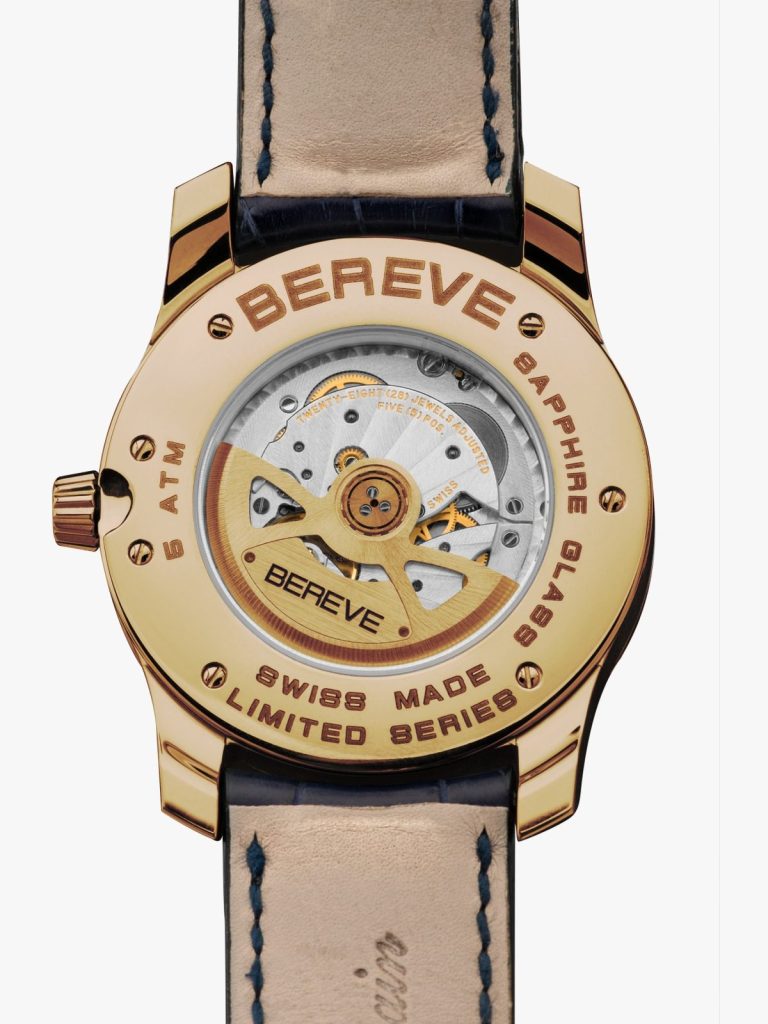

Our case is completely designed in-house, it’s made in Switzerland, by one of the most prestigious manufacturing of the horology industry.

The first step of the case manufacturing involves innovative numerical control machines. Afterwards, many details are refined using particular tools, custom-made for Bereve.

We don’t use the standard 316L stainless steel, but an advanced 316LM steel, made with the addition of molybdenum.

At Bereve, the finishing and the polishing processes are extremely delicate. These steps are handcrafted and they provide the case design with elegance and uniqueness. The detail care determines the aesthetic identity of the brand. The strong character of our cases is represented by the particular geometrical shape of one side of the case.

Bereve uses only selected anti-reflective sapphire glass.

This material is specific to Haute Horlogerie and it’s very rare in the whole world of manufacturing.The use of 316LM steel increases the construction quality and the watch aesthetics.

After the finishing and the polishing processes, that imply a series of hand-made treatments, the 316LM steel looks much more precious and it becomes really scratch, impact and corrosion resistant.

Bereve produces references in white gold and 18k gold.

At Bereve, the finishing and the polishing processes are extremely delicate. These steps are handcrafted and they provide the case design with elegance and uniqueness. The detail care determines the aesthetic identity of the brand. The strong character of our cases is represented by the particular geometrical shape of one side of the case.

Bereve uses only selected anti-reflective sapphire glass.

©Copyright. Tutti i diritti riservati.

Abbiamo bisogno del vostro consenso per caricare le traduzioni

Per tradurre i contenuti del sito web utilizziamo un servizio di terze parti che potrebbe raccogliere dati sulla vostra attività. Si prega di rivedere i dettagli nell'informativa sulla privacy e accettare il servizio per vedere le traduzioni.